How the Industrial Electric Cart Improves Manufacturing Operations?

In the evolving landscape of manufacturing operations, industrial electric carts have emerged as pivotal tools. These carts, powered by advanced battery technology, offer a sustainable and efficient way to handle materials.

They mark a significant shift from traditional methods, ensuring more streamlined and environmentally friendly operations. Conceptual Innovations excels in this field, offering advanced carts that redefine efficiency in manufacturing settings.

Our unique approach merges power and functionality, enabling industries to tackle logistical challenges effectively. The impact of these electric carts extends beyond mere transportation, fostering safer, more sustainable, and cost-efficient manufacturing processes.

Overview of Industrial Electric Carts: Integrated Technology

An industrial electric cart, specifically the motorized type, serves as a robust solution in material handling within manufacturing settings. Engineered to address the bottleneck of transporting materials from storage to production areas, this motorized cart leverages a

This feature allows it to smoothly transport up to 10,000 lbs. at the mere touch of a button. Its utility extends to towing in trains for extended transport and precise delivery of hefty loads to designated production spots.

Versatility is evident in its design, offering options to engage or disengage the motor and pivot for enhanced steering control. The not only elevates safety and productivity but also introduces a new era of efficiency in material movement, minimizing the reliance on traditional forklifts, overhead cranes, and manual labor, thereby mitigating associated risks.

Recent Advancements in Battery Technology:

The realm of battery technology has witnessed monumental strides, particularly in lithium-ion and solid-state batteries, propelling the capabilities of industrial electric carts to new heights.

- Lithium-Ion Batteries: A Leap in Energy Density have set new standards for energy storage, providing industrial carts with extended operational life and reduced need for frequent recharging.

- Their high energy density ensures that carts can handle heavier loads and operate longer, enhancing productivity in manufacturing operations.

- Solid-State Batteries: Revolutionizing Safety and Longevity

represent a significant advancement with their non-flammable nature, reducing risks and enhancing the safety profile of industrial carts. These batteries offer a longer lifespan, reducing replacement frequency and contributing to sustainable operational practices.

Enabling Heavy-Duty Applications:

The combination of increased energy density and improved safety allows industrial electric carts to undertake heavy-duty tasks previously challenging for battery-operated machines. The reliability of these advanced batteries ensures consistent performance even in demanding industrial environments.

Battery-Powered vs. Gas-Powered Industrial Carts:

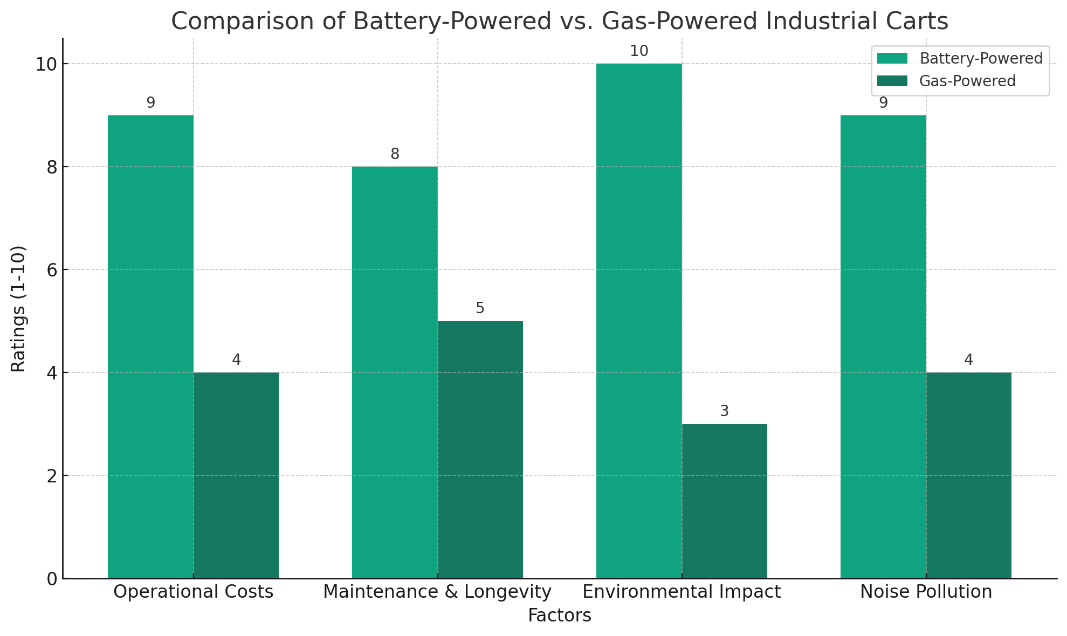

- Operational Costs: Efficiency vs. Fuel Consumption

Battery-powered carts offer significant savings in operational costs by eliminating fuel expenses and reducing energy costs through efficient battery technology. Gas-powered carts, on the other hand, incur ongoing fuel costs and are subject to fluctuating gasoline prices, impacting long-term operational budgets.

- Maintenance and Longevity: The Durability Factor

Battery-powered carts require less maintenance due to fewer moving parts and the absence of engines or exhaust systems, leading to lower maintenance costs and longer operational life. Gas-powered carts often demand frequent maintenance, including engine services and part replacements, which can lead to higher costs and potential downtime.

- Environmental Impact: Emissions and Carbon Footprint

Battery-powered carts significantly reduce emissions, contributing to a cleaner and more sustainable operating environment. In contrast, gas-powered carts contribute to greenhouse gas emissions and have a larger carbon footprint, impacting both immediate and overall environmental sustainability.

- Noise Pollution and Operational Efficiency

Battery-powered carts operate quietly, minimizing noise pollution and creating a more conducive work environment. Gas-powered carts, with their engines, contribute to higher noise levels, which can be disruptive in manufacturing settings and contribute to worker injury and absenteeism.

Noise Pollution and Operational Efficiency

The comparison chart above illustrates the differences between battery-powered and gas-powered industrial carts across several factors. The ratings, on a scale of 1 to 10, reflect the relative performance of each type of cart in the respective categories. As shown, battery-powered carts generally outperform gas-powered carts in operational costs, maintenance and longevity, environmental impact, and noise pollution.

Benefits of Using Industrial Electric Carts in Manufacturing Operations:

- Safety:

Industrial electric carts significantly reduce overexertion injuries by providing a stable and controlled means of transporting heavy loads, ensuring a safer workplace environment.

- Efficiency and Productivity:

These carts allow a single operator to move substantial loads effortlessly, minimizing the need for additional personnel and streamlining operations, leading to heightened productivity levels.

- Operational Flexibi

The versatility in cart configurations, including options for manual steering or straight-line movement, allows for tailored solutions that enhance operational efficiency and adaptability in diverse manufacturing scenarios.

This underscores the core benefits of utilizing industrial electric carts in manufacturing settings, focusing on the vital aspects of safety, efficiency, productivity, and operational flexibility.

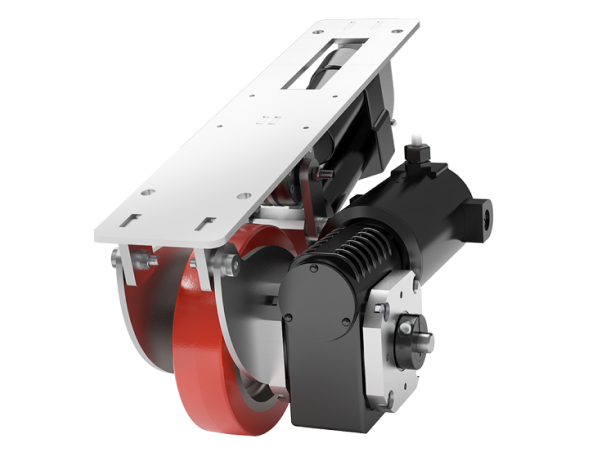

Conceptual Innovations’ Patented Technology in Action:

Conceptual Innovations’ patented technology harmoniously integrates the steering and driving motors. This fusion results in precise maneuverability and robust propulsion in their industrial electric carts, setting new industry standards.

The synergy between the steering and driving mechanisms not only doubles the weight capacity but also optimizes energy usage. Carts can handle heftier loads or operate at reduced power without compromising performance, demonstrating a leap in operational efficien

The company not only offers top-tier but also provides specialized for specific operational needs. for a tailored solution that enhances efficiency, safety, and productivity.